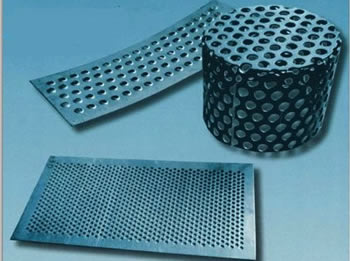

Hole sizes can vary in response to motion control, laser power or galvo systems, which are mirrors that can control laser direction. Read More…

At Edge Metalworks, we pride ourselves on providing top-notch laser cutting services to our valued customers. Our team is equipped with state-of-the-art laser cutting technologies that range from 4kw – 24kw and enable us to precisely cut a wide variety of metals and thicknesses, catering to the unique specifications of each project. Our commitment to quality ensures that our products meet the...

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Brass, Titanium, Nitinol, Nickel, Kovar and many others.

Our teams at Remaly Manufacturing Company, Inc. utilize state of the art equipment to provide you with laser cutting capabilities. Our teams provide cutting services for a wide range of materials such as steel, aluminum, stainless steel, monel and much more.

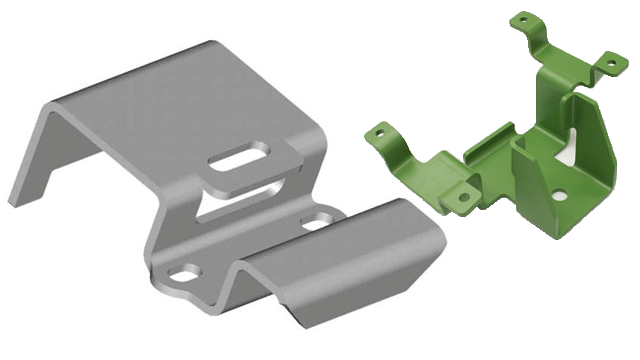

Our fiber optic metal laser cutting capabilities include Stainless steel, Aluminum, CRS and other ferrous and nonferrous metals. We can laser cut flat blanks, stencils, signs, prototypes, and custom formed fabricated parts.

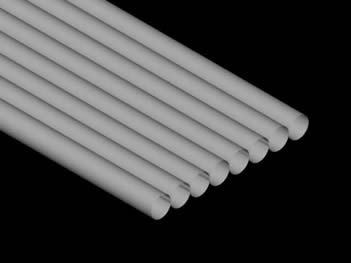

Sharpe Products specializes in custom pipe and tube bending and tube laser cutting. With three powerful, 4kW laser cutting systems, and a robotic, multi-axis 3 kW laser cutting system, we cut round, square, rectangle and open profiles, up to 6-inch OD. Typical cutouts include angles, copes, notches, perforations, slots, or other custom hole patterns, either before or after tube bending. We...

Our laser cutting services are used by leading manufacturers. We have a 10k square foot laser production facility with cutting capabilities up to .625” on steel which processes material quickly. Stocking much carbon steel allows us to pass along the savings. We serve automotive & trucking industries.

More Laser Drilling Companies

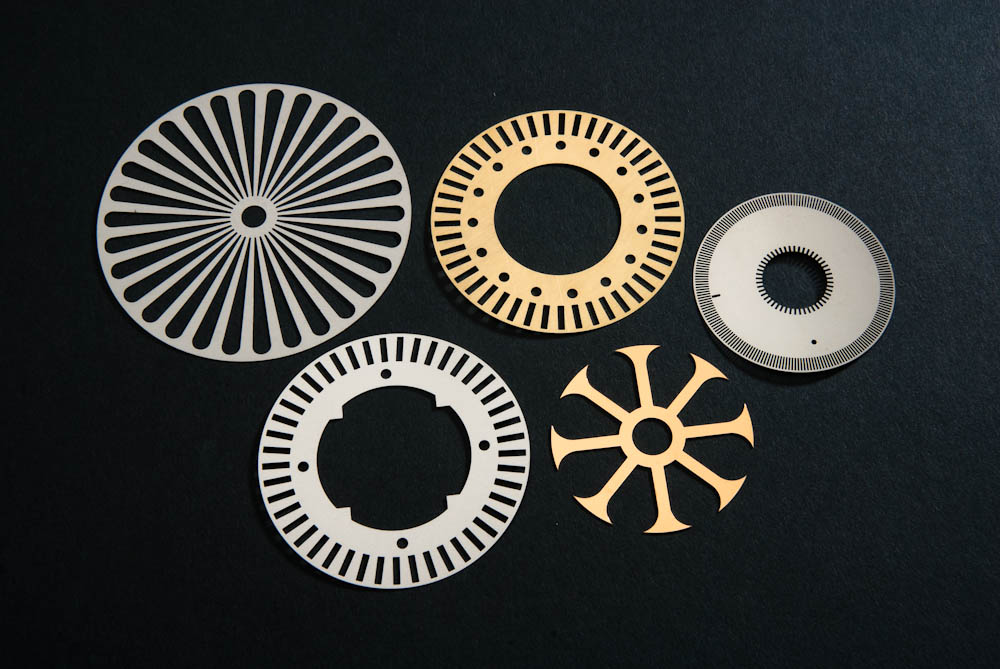

Laser drilling serves industries such as medical, semiconductor, aerospace, electronics and manufacturing, and is essential for fabricating products including engine blades, irrigation needles, fuel injectors, flow control devices and nozzle guide rings. Laser drilling, which is a laser cutting process works by precision-controlling the heat energy achieved by short, rapid laser pulsations through a combination of CNC machining and CAD computer programs. CAD is the actual computer program that takes the dimensions of the desired tool and tells the computer controlling the machine, the CNC, what to do.

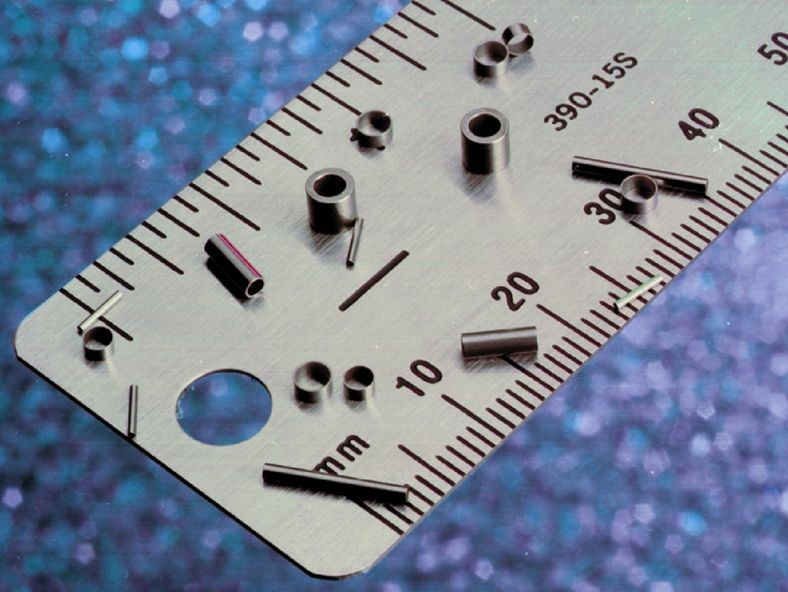

The focused laser beam is able to remove surface layer materials to form holes of varying diameters and depths. Several different laser drilling processes can be used including: single-shot laser drilling, which uses a single high-energy laser pulse; percussion drilling, which uses multiple short-duration, low-energy pulses; trepanning, where a pilot hole is created and then multiple laser pulses enlarge the hole through circular motions; and helical drilling, using multiple laser pulses in circular motions in a downward spiral.

Laser drilling can perform precise high speed drilling in virtually every existing metal and certain plastic materials such as silicone; it can also permit the drilling of holes in exotic alloys not possible with traditional methods such as wire EDM and CNC punching. Materials compatible with laser drilling include mild steels, stainless steels, titanium alloys, aluminum alloys, galvanized steels, nitinol, inconel, ceramics and diamonds.

An inexpensive process, laser drilling has been made popular due to rapid prototyping and the ability to maintain tight tolerances as small as 10-20 microns. It often works in conjunction with other laser cutters to create specialized tools such as gaskets, which sometimes have holes requiring the laser drilling as well as the laser metal cutting machine that shaped it. This is just one example of how the laser cutting industry is vital to the production of the small tools that make our world run. Aesthetically, there are also secondary services available at CNC machine shops that provide laser cutting services, such as polishing, painting and anodizing.

Broaching

Broaching CNC Machining

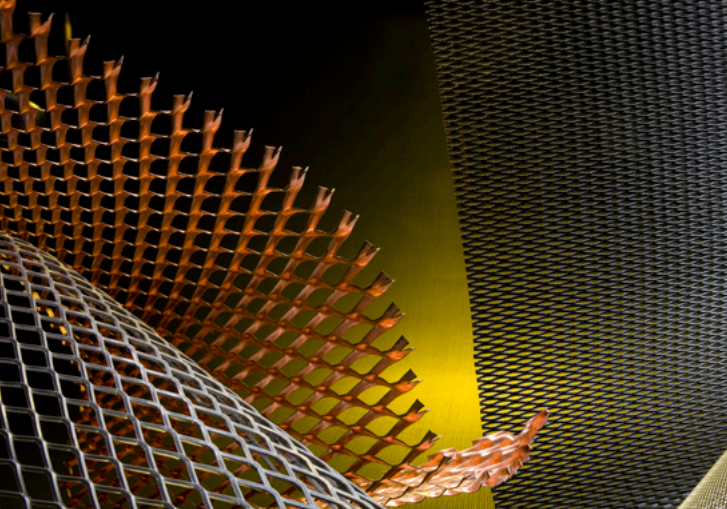

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services