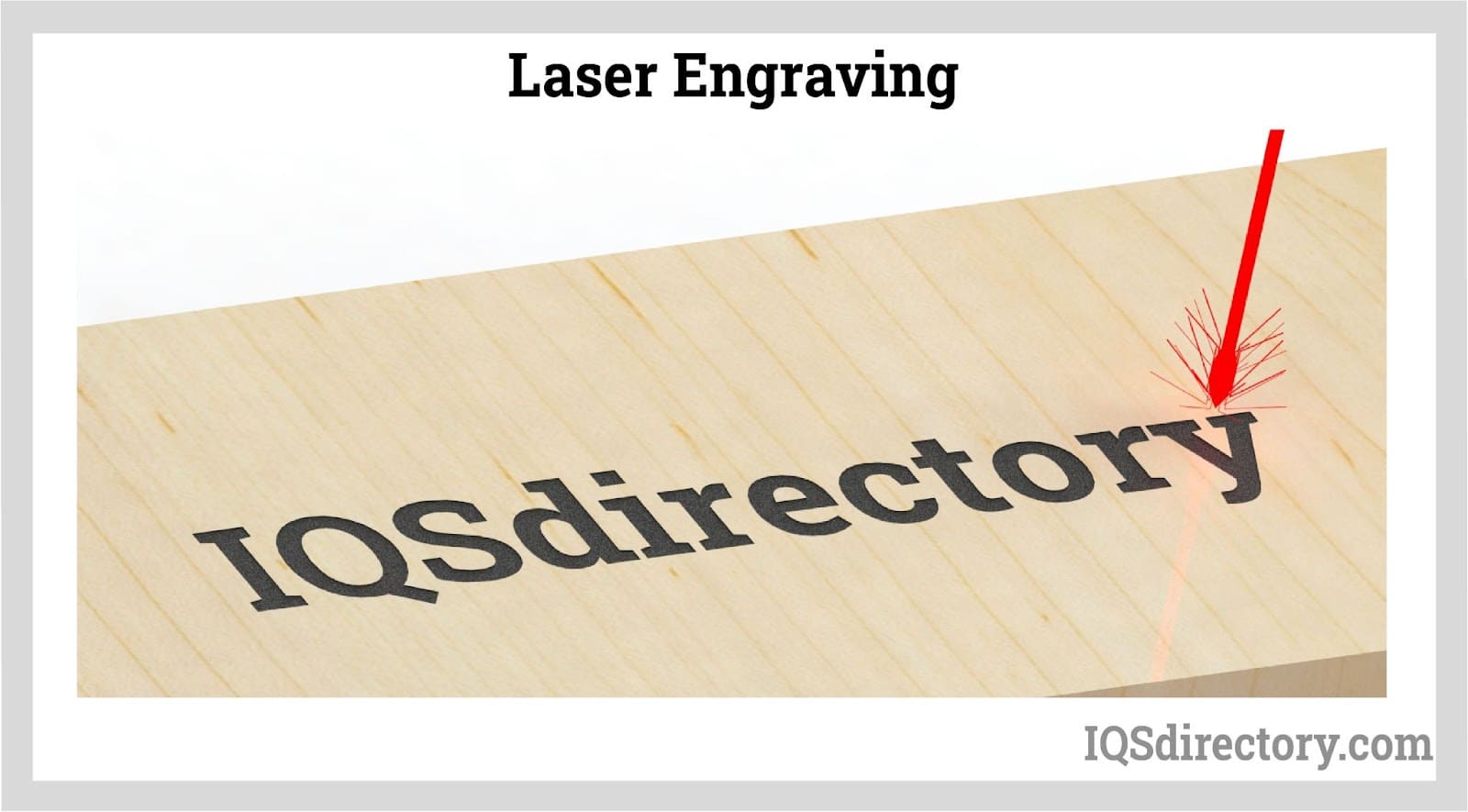

The process or art of stamping a design on a hard surface is known as engraving. An apparatus that produces a powerful beam of coherent monochromatic light is called a laser. Therefore, the process of utilizing lasers to carve an object is known as laser engraving. In a nutshell, laser engraving deliberately removes small layers of material from the treated surface, leaving behind visible marks. The laser beam acts like a chisel to leave traces on the surface by scraping away layers of the material’s surface. Read More…

At Edge Metalworks, we pride ourselves on providing top-notch laser cutting services to our valued customers. Our team is equipped with state-of-the-art laser cutting technologies that range from 4kw – 24kw and enable us to precisely cut a wide variety of metals and thicknesses, catering to the unique specifications of each project. Our commitment to quality ensures that our products meet the...

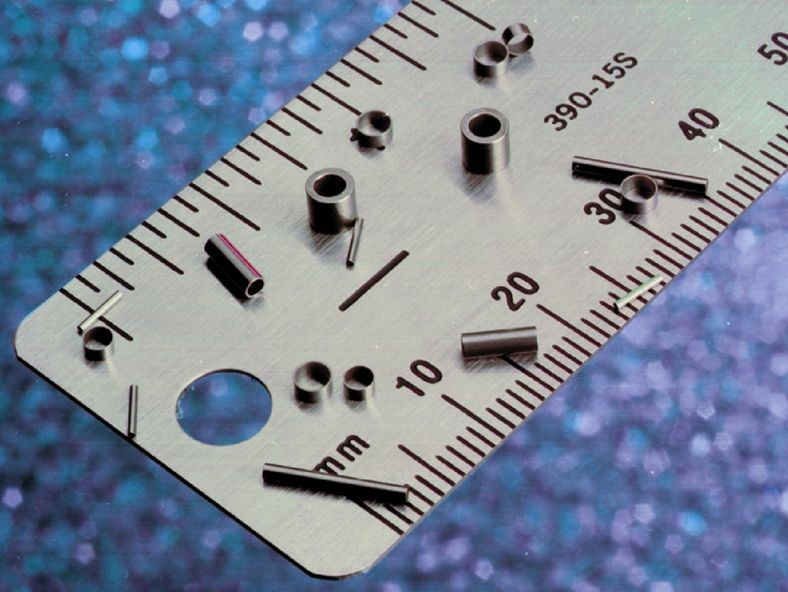

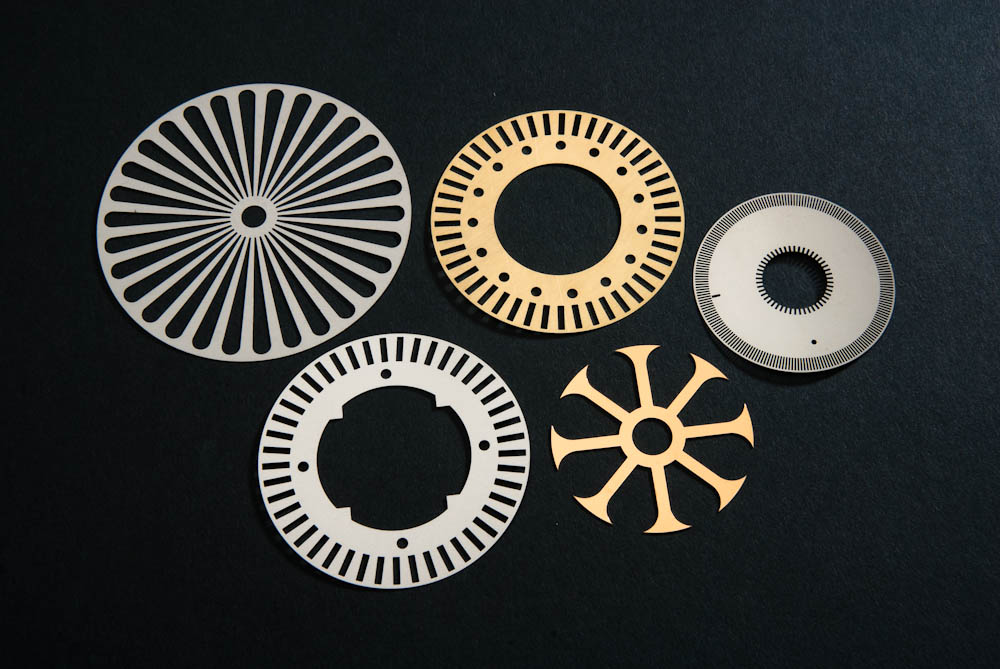

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Brass, Titanium, Nitinol, Nickel, Kovar and many others.

Our teams at Remaly Manufacturing Company, Inc. utilize state of the art equipment to provide you with laser cutting capabilities. Our teams provide cutting services for a wide range of materials such as steel, aluminum, stainless steel, monel and much more.

Our fiber optic metal laser cutting capabilities include Stainless steel, Aluminum, CRS and other ferrous and nonferrous metals. We can laser cut flat blanks, stencils, signs, prototypes, and custom formed fabricated parts.

Sharpe Products specializes in custom pipe and tube bending and tube laser cutting. With three powerful, 4kW laser cutting systems, and a robotic, multi-axis 3 kW laser cutting system, we cut round, square, rectangle and open profiles, up to 6-inch OD. Typical cutouts include angles, copes, notches, perforations, slots, or other custom hole patterns, either before or after tube bending. We...

Our laser cutting services are used by leading manufacturers. We have a 10k square foot laser production facility with cutting capabilities up to .625” on steel which processes material quickly. Stocking much carbon steel allows us to pass along the savings. We serve automotive & trucking industries.

More Laser Engraving Companies

The laser delivers concentrated energy to specific locations to produce the intense heat necessary for vaporization. The interactions between a laser and a substance might vary depending on the materials. The primary mechanism of action for ablation on tougher surfaces is the displacement of tiny particles from the substrate by the laser's focused beam. The depth of engraving can reach 100 um and beyond.

Types of Laser Engraving

Cutting Engraving

Cutting engraving applies the cutting technique to create the desired pattern on the material's surface. To do this, the pattern is first broken down and expressed as a series of lines, then cut with a laser to create the pattern that the cutting line represents.

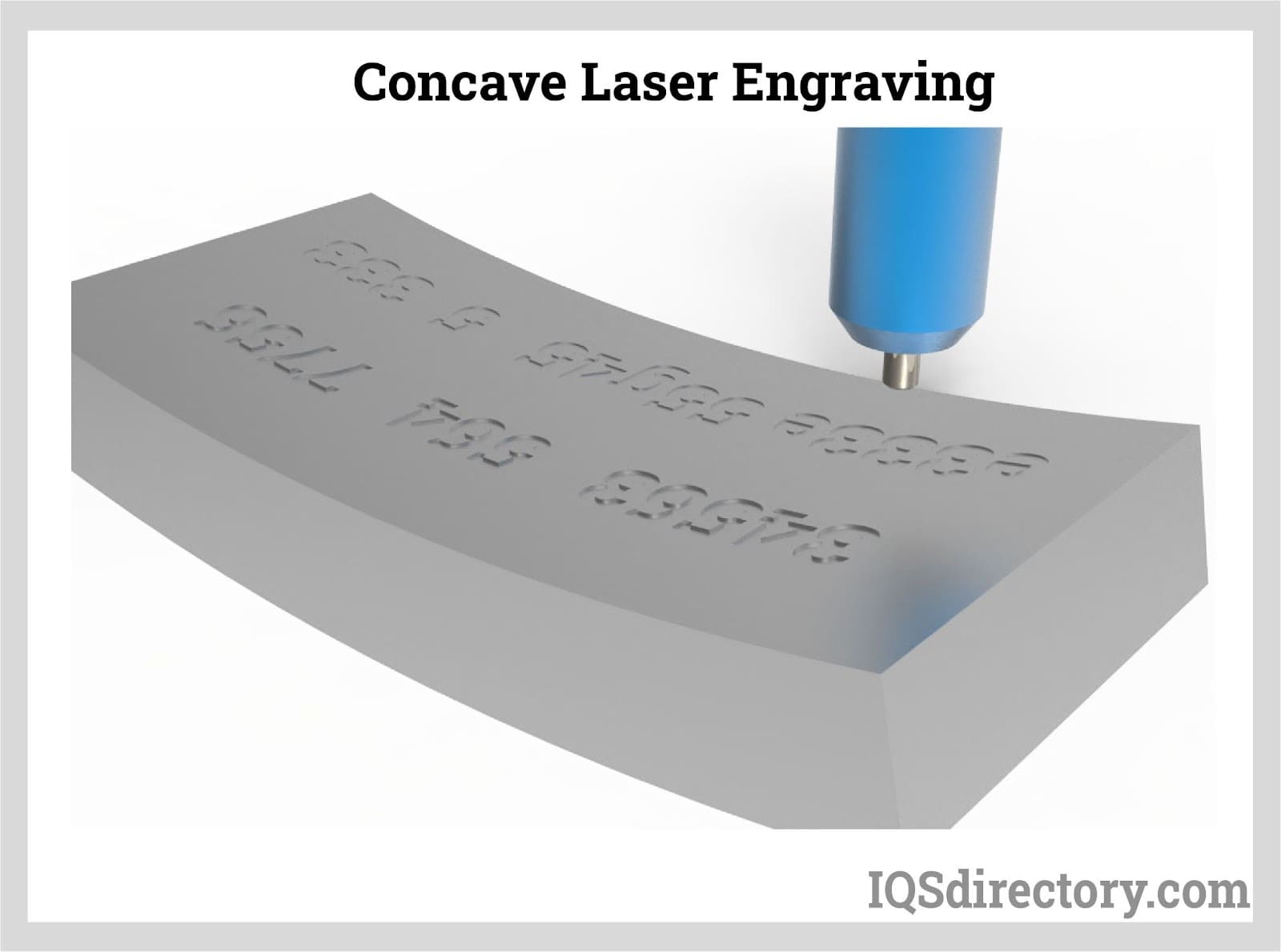

Concave Laser Engraving

In the process of concave engraving, the laser beam follows the path of the needed pattern to create the design as voids. Only a portion of the pattern is removed, leaving the material's surface intact for the remainder of the pattern. Here, there are two instances. The same cutting force is used in the first scenario for each point on the pattern. The etched pattern is mostly reflected in the outline shape.

The second scenario is based on the pattern's contrast and light-dark distribution. The bright area of the pattern is not cut at all or cut less, and the dark part of the pattern is cut more. The former is appropriate for engraving patterns primarily based on the look, such as characters, animals, plants, and other designs; the latter is more appropriate for engraving designs that include details, such as characters’ facial expressions.

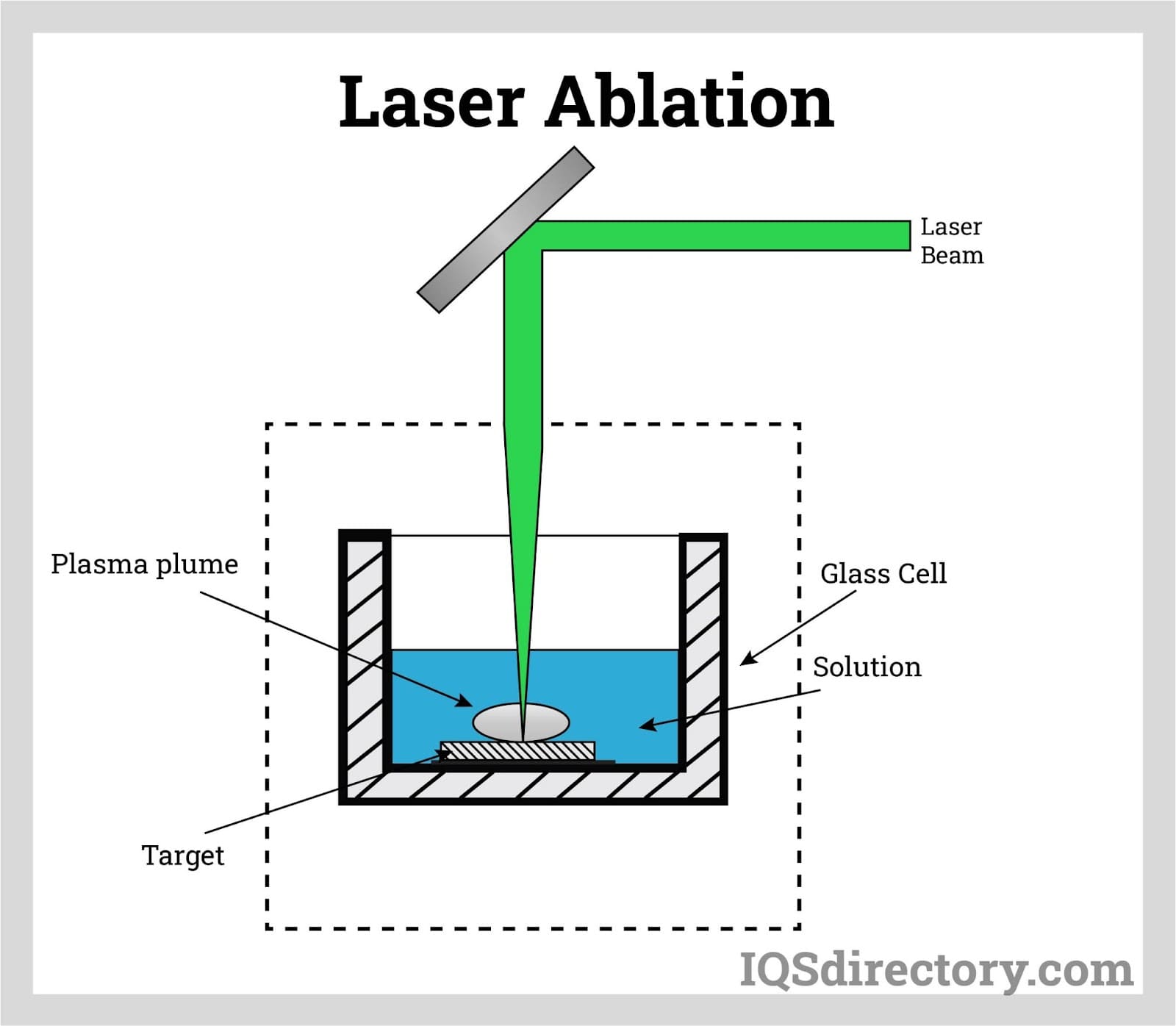

Laser Ablation

Laser ablation is a technique in which exposing a surface to a laser beam can remove material from solid or, occasionally, liquid surfaces. The substance is heated by the absorbed laser energy at low laser flux and evaporates or sublimates. The substance is normally transformed into plasma at high laser flux. The term "laser ablation" typically refers to the removal of material using a pulsed laser.

However, if the laser intensity is strong enough, it is possible to ablate material using a continuous wave laser beam. Every material has an ablation threshold. When that limit is reached, the radiation-damaged area vaporizes into vapors. If a material is pre-heated, such as aluminum, it will reach the ablation threshold more quickly. The material may be laser etched quicker and deeper this way.

Concave Laser Engraving

Contrary to concave die engraving, this engraving procedure only cuts the material surrounding the pattern; the design's material is left uncut. The cutting force at each place is the same. Convex engraving elevates the design by removing the material around the pattern. This engraving style is typically used for carving letters, outlining graphics, and other simple patterns that don't require a lot of detail.

In this case, the laser energy is constant throughout the pattern. The laser power levels and the material thickness should be used with caution. Edge burns might be more obvious since one would be carving out their design. Convex engraving can't generate detailed engravings, but it's perfect for creating elaborate patterns while maintaining the workpiece's structural integrity.

Benefits of Laser Engraving

- Laser engraving brings better durability, especially in harsh conditions where the imprint could get dirty or worn.

- The method is unrestricted by the drawbacks of mechanical cutting instruments, which deteriorate and get dull over time. This wear lowers the engraving's quality. For accuracy, the laser is computer-controlled. As a result, the engraving will be made according to the exact specifications and will be the same for all subsequent engravings of the same design.

- Rapid output is crucial in temporary construction zones and other environments.

- Due to the automated nature of laser engraving, it is not slowed down by the need to change out cutting tools or by the labor-intensive hand cutting required by conventional procedures. Previously thought to be impractical, intricate patterns with fine details can now be swiftly and effectively etched. It only takes a few hours to engrave something that would have taken weeks.

- A non-contact processing method is laser engraving. Its benefits over conventional machining techniques include the absence of noise pollution, tool wear, and debris pollution.

- Laser engraving produces more legibility when signing because of the depth of the letters.

- Numerous materials with different degrees of thickness can be engraved using laser technology. One can carve patterns on curved, uneven, and other intricate surfaces of 3D objects. Patterns can be engraved with lasers in places that are challenging to access using other methods.

Choosing the Right Laser Engraving Company

To ensure you have the most productive outcome when selecting a laser engraving company, it is important to compare several laser engraving businesses using our directory of laser engraving businesses. Each laser engraving company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each laser engraving company website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Broaching

Broaching CNC Machining

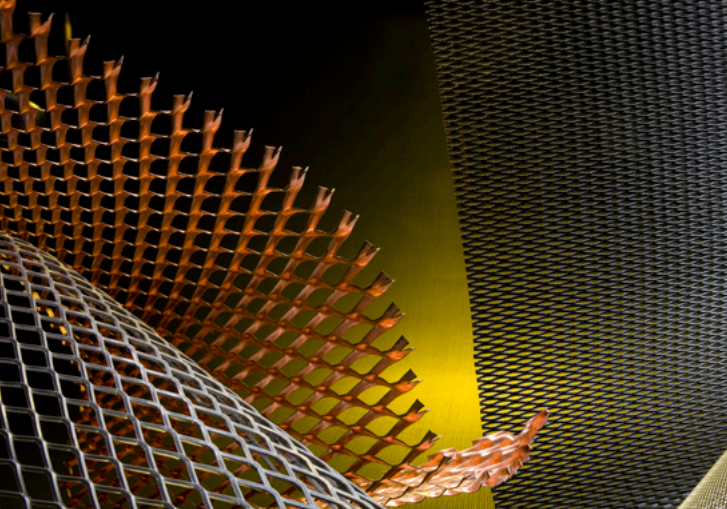

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

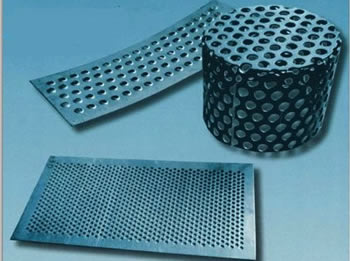

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

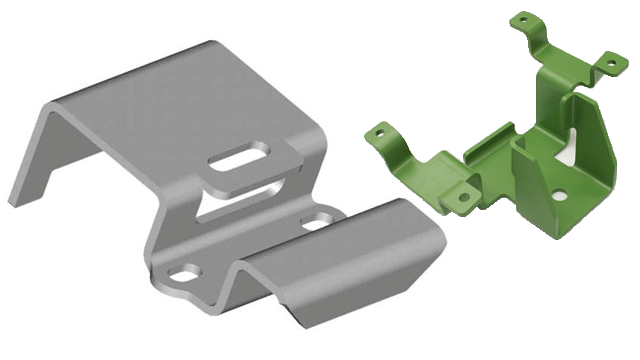

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

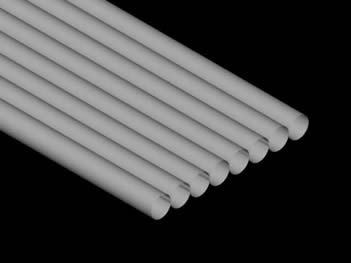

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services