Tech-Etch, Inc.

Tech-Etch, Inc.Request A Quote

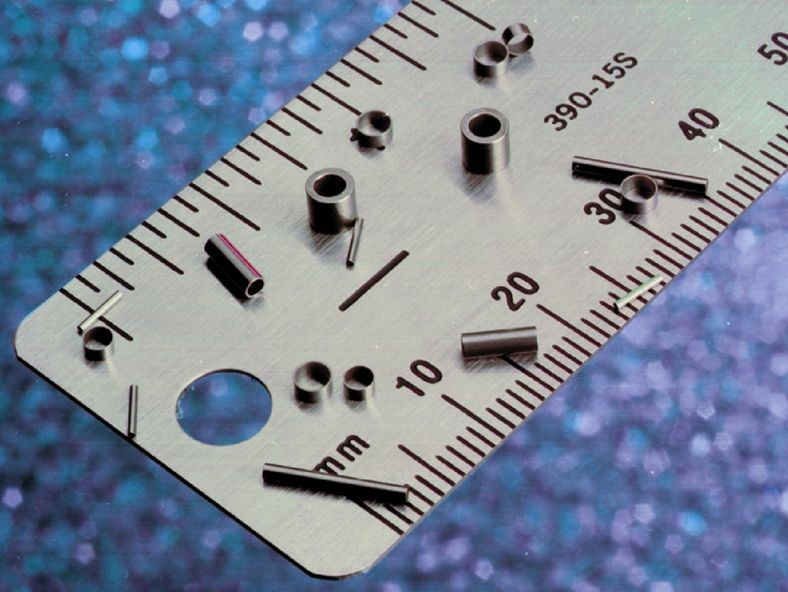

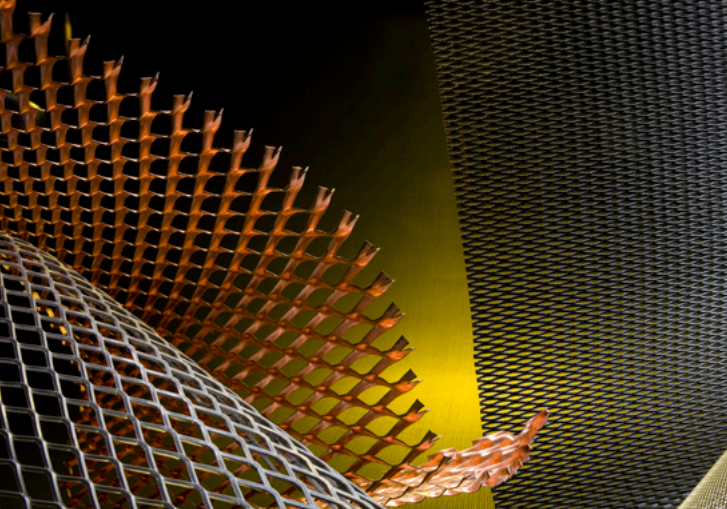

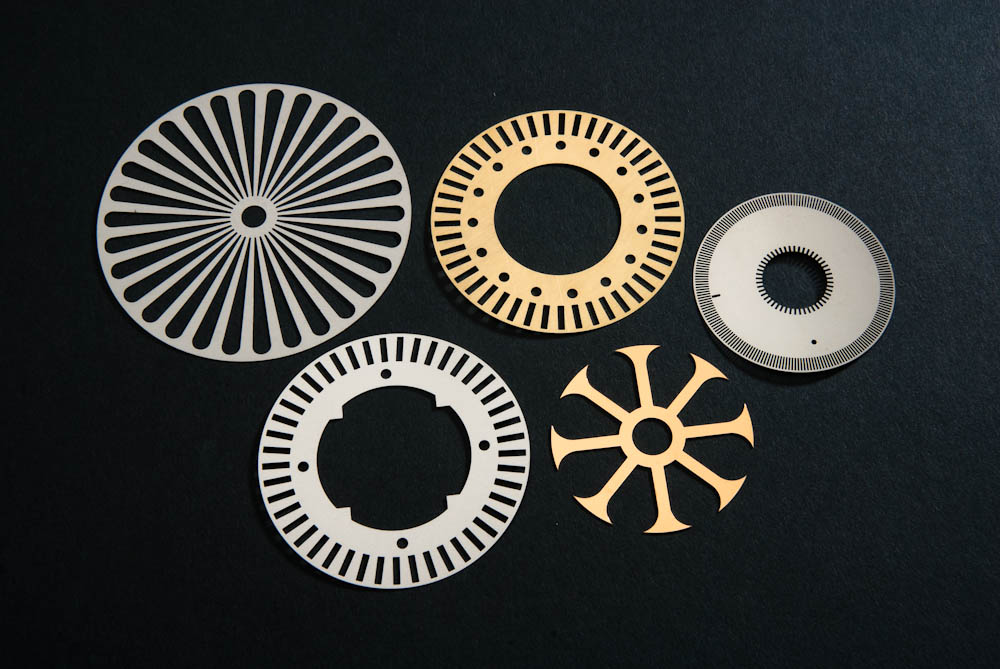

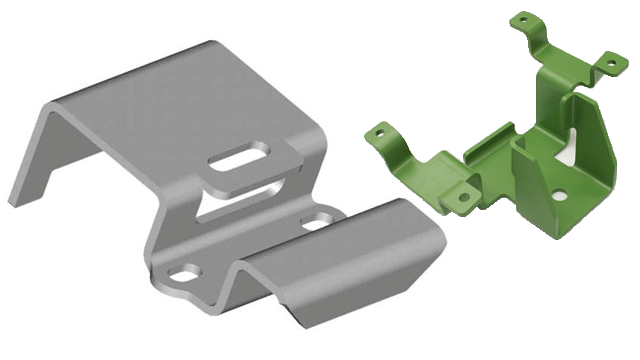

Plymouth, MATech-Etch, Inc. is a leading provider of precision thin metal parts and flexible circuits. The company was founded in 1966 and has since then grown into a multi-faceted manufacturing and engineering organization with a strong focus on delivering quality products to its customers. Tech-Etch's core competency lies in its ability to manufacture thin metal parts through a variety of processes, including photoetching, stamping, and laser cutting. Laser cutting is one of Tech-Etch's primary service offerings, and it has invested in advanced laser cutting equipment to meet the increasing demand for precision metal parts. Tech-Etch's laser cutting service allows customers to cut a wide range of materials, including stainless steel, copper, brass, and nickel alloys, with thicknesses ranging from 0.001 inches to 0.125 inches. One of the key advantages of laser cutting is its ability to produce precise and intricate shapes that are difficult or impossible to achieve with traditional machining methods. Tech-Etch's laser cutting equipment uses computer-controlled lasers to cut parts to extremely tight tolerances, ensuring that the finished product meets the customer's exact specifications. Tech-Etch's laser cutting capabilities also allow for rapid prototyping and quick-turn production runs, making it an ideal solution for customers who require high-quality metal parts in short lead times. In addition to cutting parts to size, Tech-Etch's laser cutting service can also perform additional operations such as marking, engraving, and etching, adding further value to the finished product. With over 50 years of experience in the metalworking industry, Tech-Etch has developed a reputation for delivering quality products and exceptional customer service. Its laser cutting service is just one of the many ways that the company continues to meet the evolving needs of its customers in a wide range of industries, including aerospace, medical, and defense.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

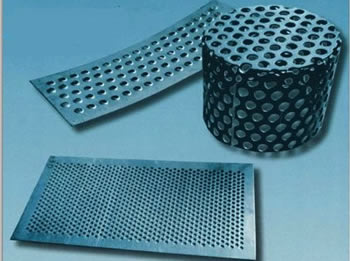

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

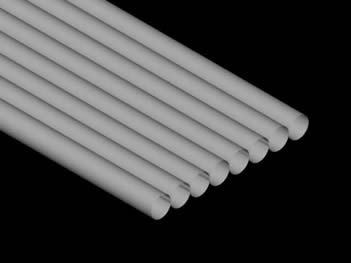

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services