Great Lakes Engineering, Inc.

Great Lakes Engineering, Inc.Request A Quote

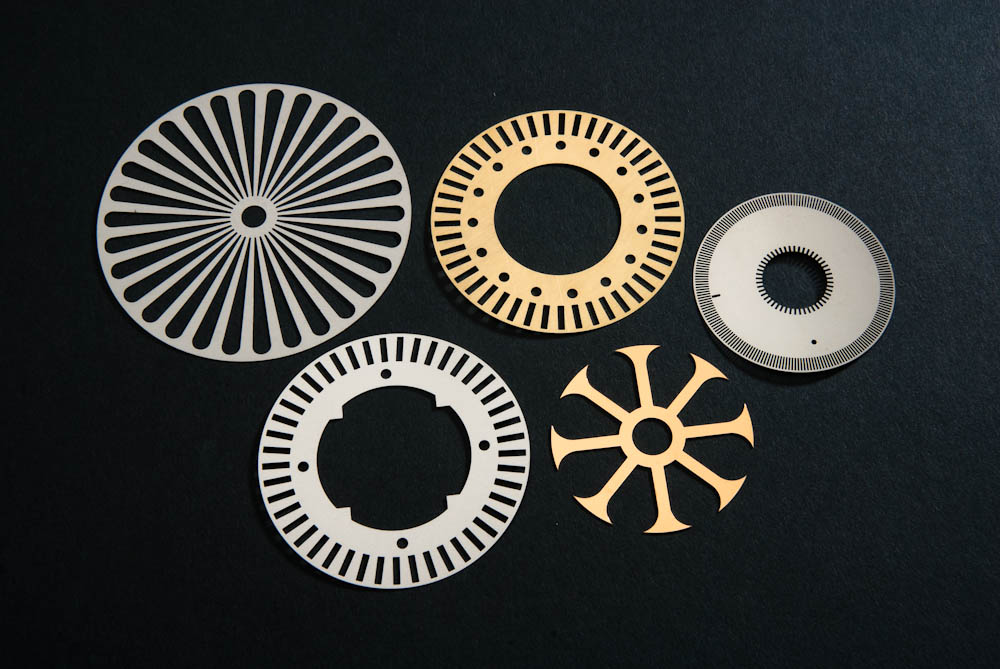

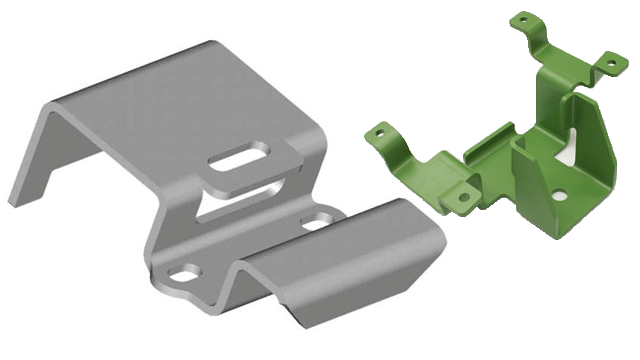

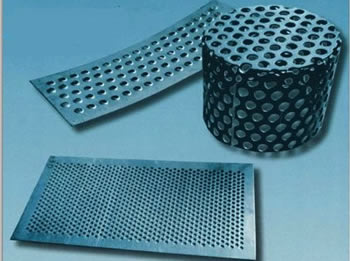

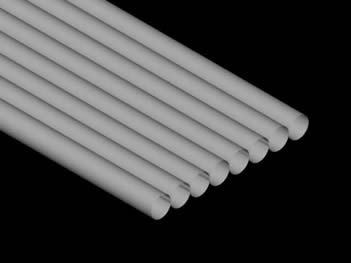

Maple Grove, MN | 763-425-4755At Great Lakes Engineering, we are a trend-setting manufacturer of surface mount stencils, precision laser-cut parts, and photochemical-etched parts. Our wide range of materials includes Stainless Steel, Copper, Brass, Titanium, Nitinol, Nickel, Kovar, and many others, but we do not work with glass, plastics, or aluminum. Our specialty is working with very thin materials ranging from .001” to .030” thick, and we can offer a wide range of capabilities and materials to meet your needs. In some instances, we can also work with thicker materials, so please give us a call if you have any questions. As a leading provider of high-quality laser cutting services, we have the capability to cut materials such as stainless steel, aluminum, brass, copper, and more, and we also offer custom laser cutting services to meet the unique needs of our clients. Our state-of-the-art equipment and experienced team of professionals allow us to deliver precision laser cutting solutions that meet the unique needs of our clients. We are proud to have some of the best turn times in the manufacturing industry, and we are constantly investing in our equipment and personnel to ensure that we remain at the forefront of the laser cutting industry. Our products, services, and capabilities are designed to provide the best laser cutting solutions for various industries, including the defense, medical, electronics, aerospace, aviation, telecommunications, energy, and even decorative applications. Great Lakes Engineering has several certifications and registrations, including ISO 9001:2008 #A1476US, Central Contract Registration (CCR) #105766542, Federal Government Specific Code (CAGE) #59VC8, International Traffic in Arms Regulations (ITAR) #M23724, and Online Representations and Certifications (ORCA) #105766542. These certifications and registrations demonstrate our commitment to providing high-quality laser cutting solutions that meet the unique needs of our clients while also adhering to the highest standards of quality and safety. In summary, at Great Lakes Engineering, we are committed to delivering high-quality laser cutting solutions that meet the unique needs of our clients. Our products, services, and capabilities are designed to provide the best laser cutting solutions for various industries, and we are constantly investing in our equipment and personnel to ensure that we remain at the forefront of the laser cutting industry. Contact us today to learn more about how we can assist with your laser cutting needs.

Broaching

Broaching CNC Machining

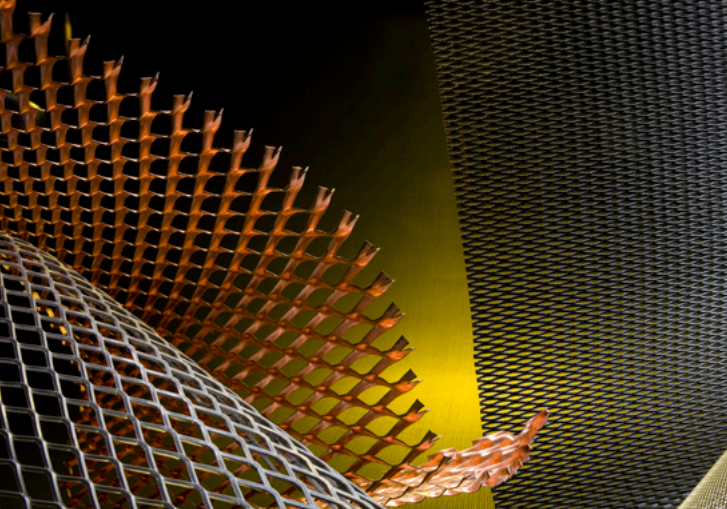

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

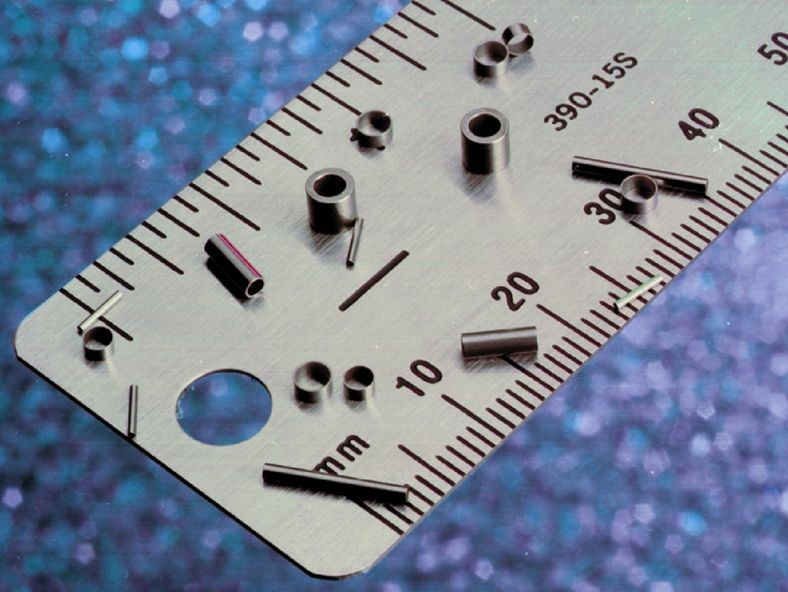

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services