Laser cutting is a method most commonly used to cut metal, but there has recently been an increase in using laser cutting technology to machine other materials such as acrylic displays and lightweight foam and sandwich boards. Along with this trend, there has also been an increased demand for materials to be cut to mitre or to be cut at a slant. Standard laser cutting machinery is designed so the laser meets the material at a 90 degree angle, however more and more diverse tools are being created and utilized in the industry to allow for more options. These tools are installed on the laser cutting machinery, which greatly increase the machining range as well as allow for slanted cutting edges.

With the addition of these tool installations, material is able to be cut at 45 degree angles with the tool positioned at a slant, so that wedges can be cut out. The wedge then allows the material to be bent into a 90 degree angle where the top outer layer is undamaged and a perfect outer edge is the result. Acrylic and similar materials can be furnished with V-grooves, bevels, and counterbores through the use of a special milling cartridge. These methods are ideal for cutting sandwich and lightweight boards to mitre. These materials are then most often used in applications such as model making, mounts, store construction, and exhibition/promotional stands and displays.

Another special demand that has become more common in the industry is laser cutting contoured surfaces. When it comes to engraving contoured surfaces with laser cutters, 3-axis laser scan heads are used to make extremely accurate cuts. These are used on materials including plastics, wood, and metal. Scan heads such as these are also an excellent choice for engraving glass because the laser creates microscopic cracks and lifts cracked material off of the surface. As the laser cutting industry continues to grow and evolve, more and more innovations are created for new applications and specific cutting demands. For more detailed information about these processes and services contact a laser cutting service provider near you.

Broaching

Broaching CNC Machining

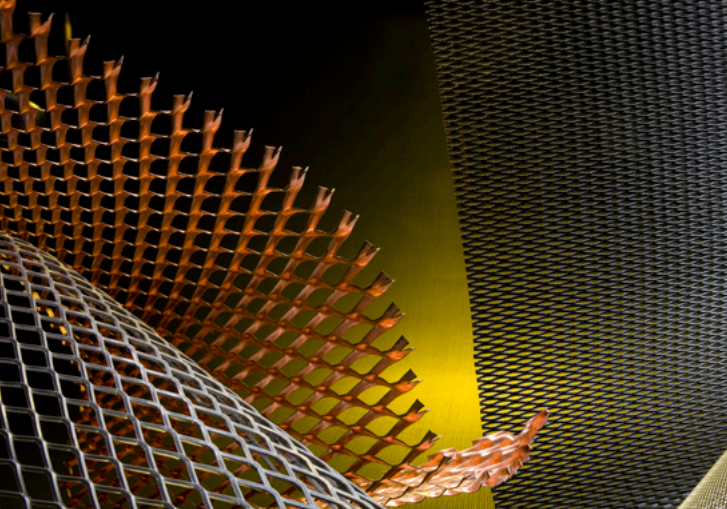

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

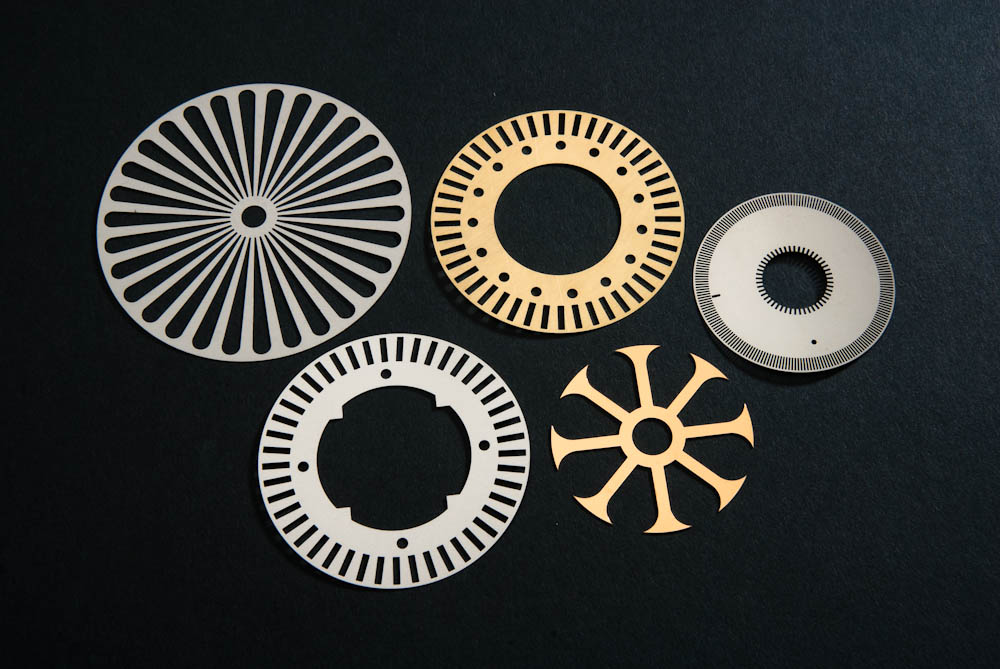

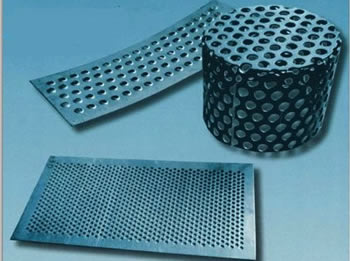

Metal Fabrication Perforated Metals

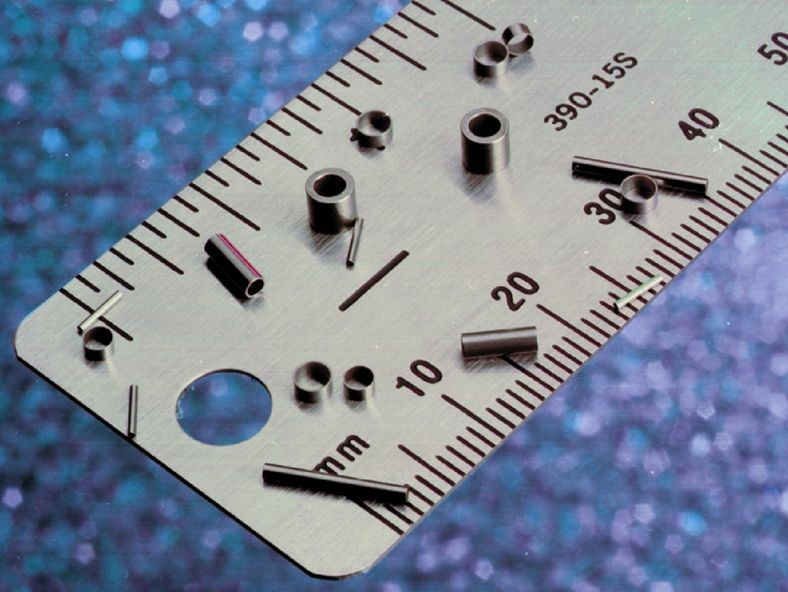

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

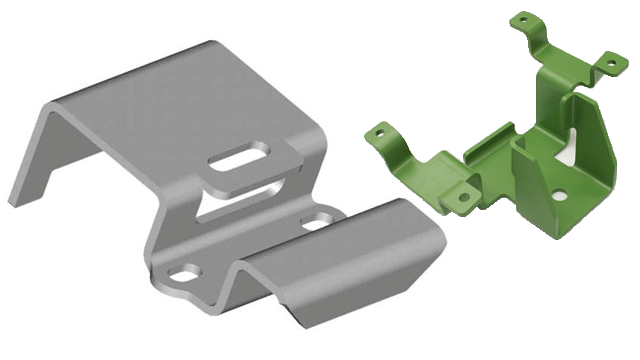

Metal Stampings Sheet Metal Fabrication

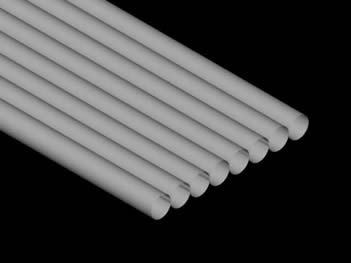

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services