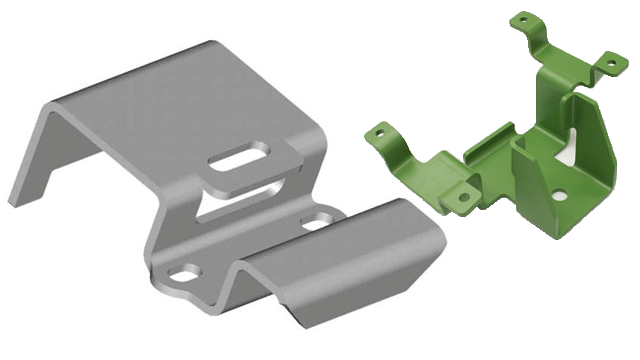

Laser cutters create holes and patterns through laser cutting services such as laser micromachining, laser drilling, laser etching and laser engraving, some of which allow 3D shaping. Industries that utilize laser cutters to assist in the fabrication of parts include medical, automotive, manufacturing, transportation, aerospace and electronics. Read More…

At Edge Metalworks, we pride ourselves on providing top-notch laser cutting services to our valued customers. Our team is equipped with state-of-the-art laser cutting technologies that range from 4kw – 24kw and enable us to precisely cut a wide variety of metals and thicknesses, catering to the unique specifications of each project. Our commitment to quality ensures that our products meet the...

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Brass, Titanium, Nitinol, Nickel, Kovar and many others.

Our teams at Remaly Manufacturing Company, Inc. utilize state of the art equipment to provide you with laser cutting capabilities. Our teams provide cutting services for a wide range of materials such as steel, aluminum, stainless steel, monel and much more.

Our fiber optic metal laser cutting capabilities include Stainless steel, Aluminum, CRS and other ferrous and nonferrous metals. We can laser cut flat blanks, stencils, signs, prototypes, and custom formed fabricated parts.

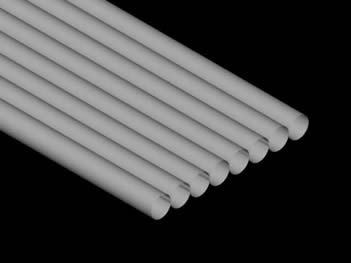

Sharpe Products specializes in custom pipe and tube bending and tube laser cutting. With three powerful, 4kW laser cutting systems, and a robotic, multi-axis 3 kW laser cutting system, we cut round, square, rectangle and open profiles, up to 6-inch OD. Typical cutouts include angles, copes, notches, perforations, slots, or other custom hole patterns, either before or after tube bending. We...

Our laser cutting services are used by leading manufacturers. We have a 10k square foot laser production facility with cutting capabilities up to .625” on steel which processes material quickly. Stocking much carbon steel allows us to pass along the savings. We serve automotive & trucking industries.

More Laser Cutter Companies

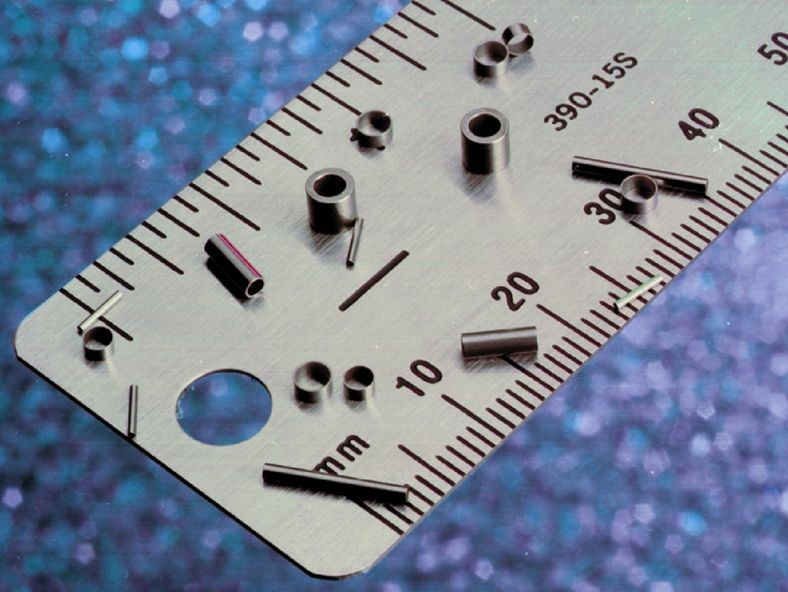

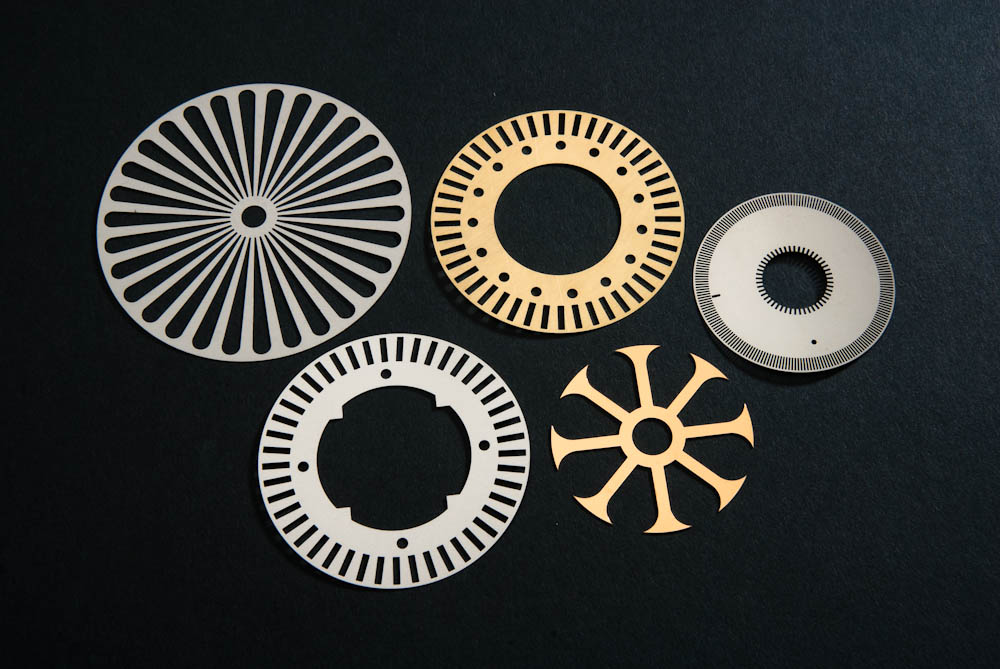

Due to the variety of laser cutter services, there is a long list of applications made available through laser cutting; microwashers, optical apertures, microfluidic channels, cell phone parts, precision miniature gears, catheters and flex circuits are just a few.

The most common type of industrial laser used by laser cutters is a CO2 laser, which is one of the highest powered lasers, which also features continuous wave. Two other examples are Nd lasers, which have low-repetition speed but are high energy lasers, and Nd-YAG lasers, which are very high energy lasers. The lasers are controlled during the cutting process by a combination of CNC and CAD computer systems. There are different methods employed by laser cutters to cut materials. Vaporization, ablation, melt and blow, thermal stress cracking and cold cutting are a few of the techniques. Laser cutters use assist gases such as nitrogen or carbon dioxide to prepare newly cut surfaces for painting or corrosion resistance, two treatments among many that can be applied to laser cut products.

Three different machine configurations usually assist laser cutters: moving material, with a stationary cutting laser head under which the material moves; hybrid, in which a table moves on the x-axis and the laser head moves along the y-axis; and a flying optic machine, which has a stationary table head and a moving table that moves over the work-piece along both horizontal directions. Materials that laser cutters commonly cut through include polymers, ceramics, stainless steel, titanium, brass, epoxy materials, thin metal foils and more. Laser cutters do have a few disadvantages, most of which involve the typical drawbacks of hot cutting. The material being cut gets very hot, so in narrow areas thermal expansion, burring and warping may be a problem.

Laser cutters have an advantage over their direct-contact process competitors because laser cutting is non-contact and does not distort or stress materials in process. Machines used by laser cutters are low-maintenance, but they provide high accuracy and consistency through lasers that are able to drill sub micron holes and focus to spot sizes as small as 10-20 microns. Laser cutters are capable of creating tighter accuracies on a smaller scale than any other provider of metal cutting.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

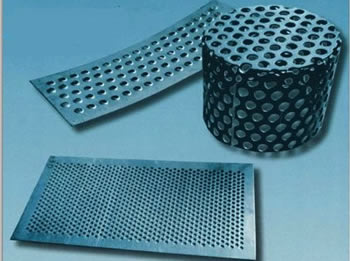

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services