Using a powerful beam of light from a computer-controlled laser, surface layers are melted and blown away or vaporized. The beam of the laser is an extremely focused radiation of a wavelength, meaning the beam will not dissipate like conventional light beams. Read More…

At Edge Metalworks, we pride ourselves on providing top-notch laser cutting services to our valued customers. Our team is equipped with state-of-the-art laser cutting technologies that range from 4kw – 24kw and enable us to precisely cut a wide variety of metals and thicknesses, catering to the unique specifications of each project. Our commitment to quality ensures that our products meet the...

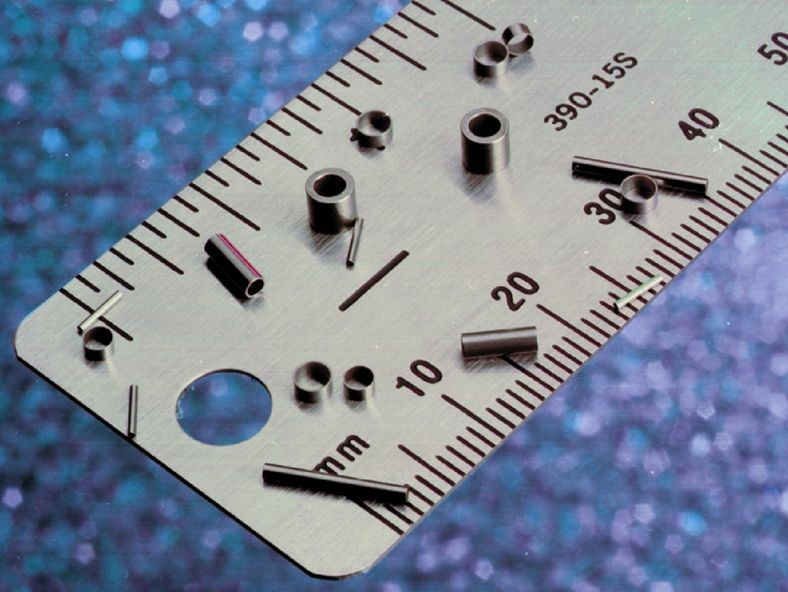

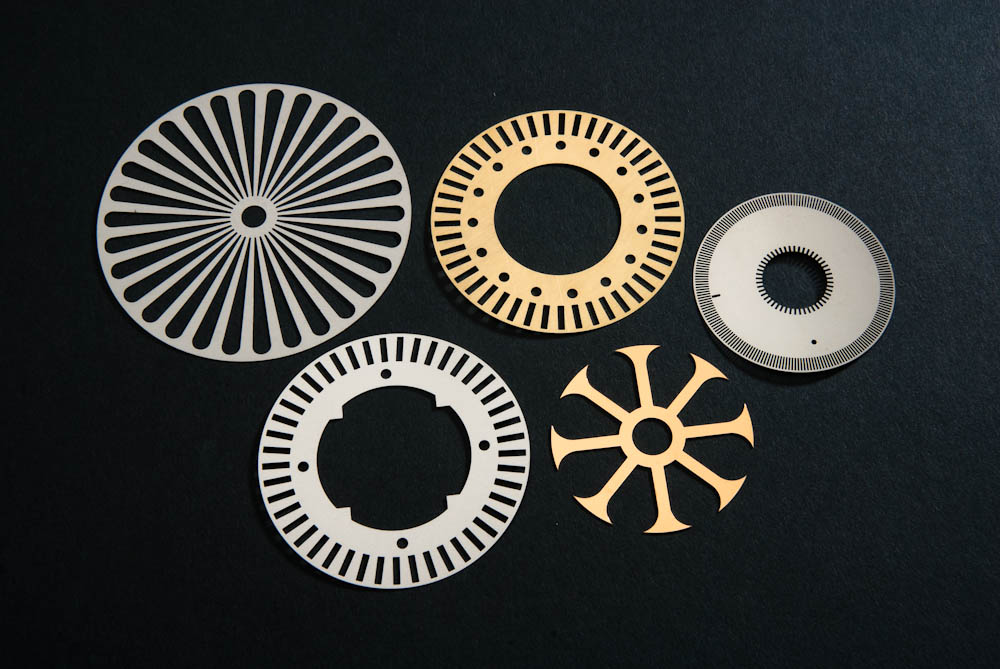

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Brass, Titanium, Nitinol, Nickel, Kovar and many others.

Our teams at Remaly Manufacturing Company, Inc. utilize state of the art equipment to provide you with laser cutting capabilities. Our teams provide cutting services for a wide range of materials such as steel, aluminum, stainless steel, monel and much more.

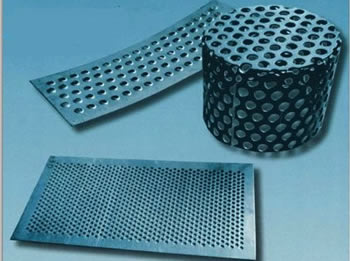

Our fiber optic metal laser cutting capabilities include Stainless steel, Aluminum, CRS and other ferrous and nonferrous metals. We can laser cut flat blanks, stencils, signs, prototypes, and custom formed fabricated parts.

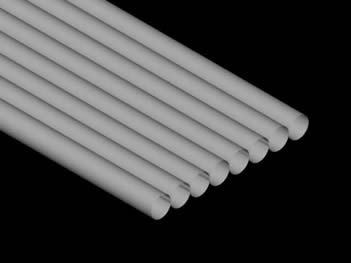

Sharpe Products specializes in custom pipe and tube bending and tube laser cutting. With three powerful, 4kW laser cutting systems, and a robotic, multi-axis 3 kW laser cutting system, we cut round, square, rectangle and open profiles, up to 6-inch OD. Typical cutouts include angles, copes, notches, perforations, slots, or other custom hole patterns, either before or after tube bending. We...

Our laser cutting services are used by leading manufacturers. We have a 10k square foot laser production facility with cutting capabilities up to .625” on steel which processes material quickly. Stocking much carbon steel allows us to pass along the savings. We serve automotive & trucking industries.

More Laser Machining Companies

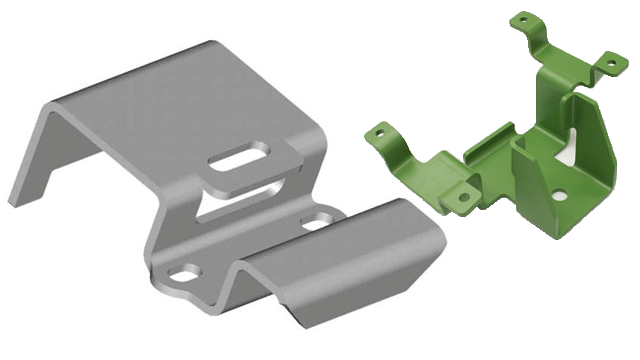

Some laser beam machining services include drilling, graining and 3-D shaping. Serving industries such as medical, aerospace, telecommunication and microtechnology, laser machining applications include thin material processing, thin film patterning, wafer coring and hole drilling. These are just a few of the vast amounts of tools produced by laser cutting machines, since every machine in the manufacturing industry requires such parts.

In laser beam machining, the beam may be shaped in two different ways: either through beam focusing, which uses an optical system to focus the laser beam on a particular size of spot, or through a mask, which utilizes geometric optic properties. Once the beam is shaped, it is controlled through a stable motion system, which is a combination of CNC and CAD computer systems, to achieve high edge quality during laser-material interaction. Assist gases such as nitrogen or carbon dioxide are then used in conjunction with laser machining to prepare newly cut surfaces for painting or corrosion resistance. Materials that can be laser machined include plastics, ceramics, cast iron, precious metals, glass and titanium.

Laser machining services have distinct advantages over conventional cutting processes such as thermal machining, mechanical machining, arc welding, EDM and flame cutting. Laser-machined parts have a condition of nearly zero edge deformation, roll-off or edge factor, leaving very little burring on part edges. Because it is often directed by CNC, laser machining rarely makes mistakes and is able to mass produce the same item quickly and efficiently. Laser machining is faster than conventional tool-making techniques and has a quicker turnaround for parts regardless of complexity because design changes can be easily accommodated.

Fewer technicians are required and safety can be assured, unlike arc welding, which requires individual workers and can be very dangerous. However, laser machining is costly, mostly because it uses a vast amount of energy to run. It is not negotiable for bulk material, nor is it able to operate on a macro scale. That is why CNC machine shops are around, so that individual companies do not need to purchase these machines individually, but can take their designs to professional laser cutters, knowing the quality of their product is insured.

Broaching

Broaching CNC Machining

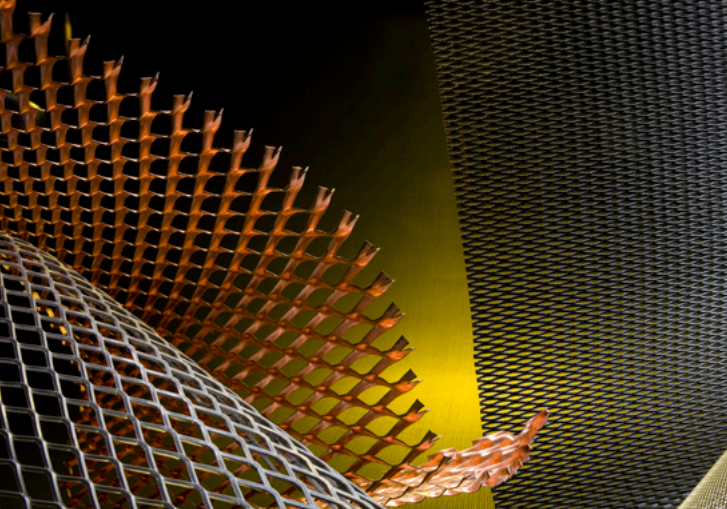

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services