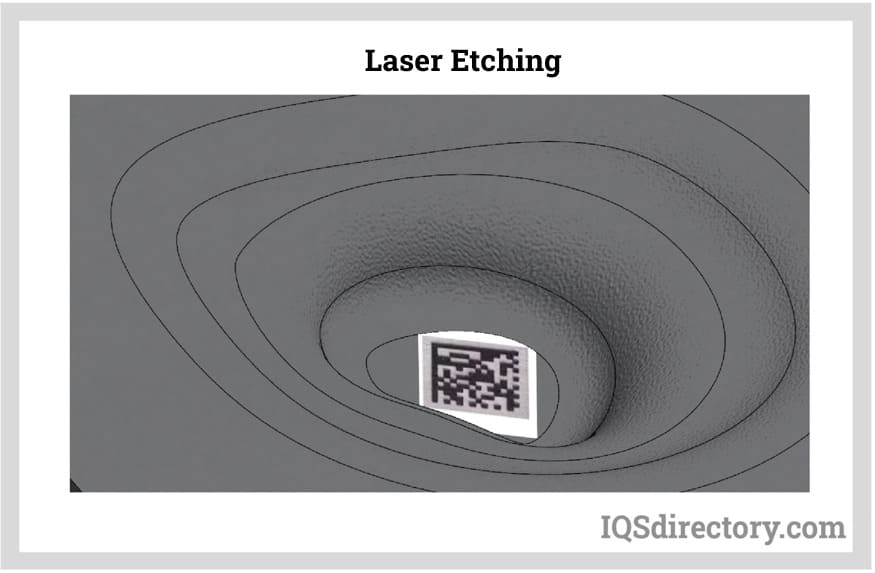

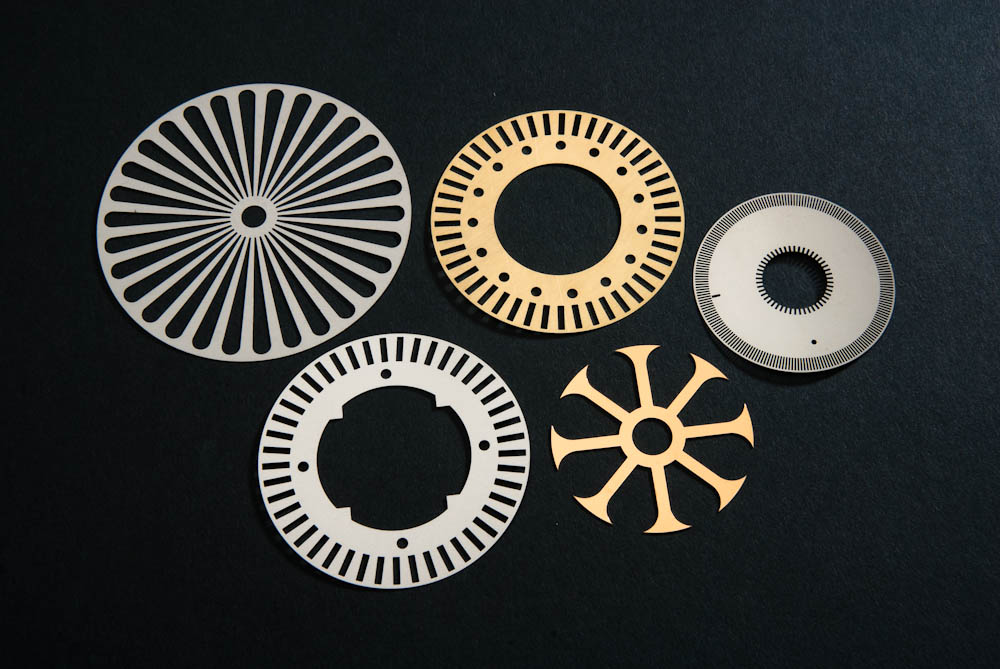

Laser etching leaves tracing by melting the surface of items and products. It falls within the more general category of laser marking, which also encompasses laser engraving and annealing. Laser etching is highly adaptable and works with the majority of metals. The laser beam concentrates a lot of energy into a small area to create a raised mark. The material’s surface melts and enlarges as a result. This can give the material a gray, white, or black hue. Permanent markings like data matrix codes, serial numbers, barcodes, and emblems are most frequently created by etching. Read More…

At Edge Metalworks, we pride ourselves on providing top-notch laser cutting services to our valued customers. Our team is equipped with state-of-the-art laser cutting technologies that range from 4kw – 24kw and enable us to precisely cut a wide variety of metals and thicknesses, catering to the unique specifications of each project. Our commitment to quality ensures that our products meet the...

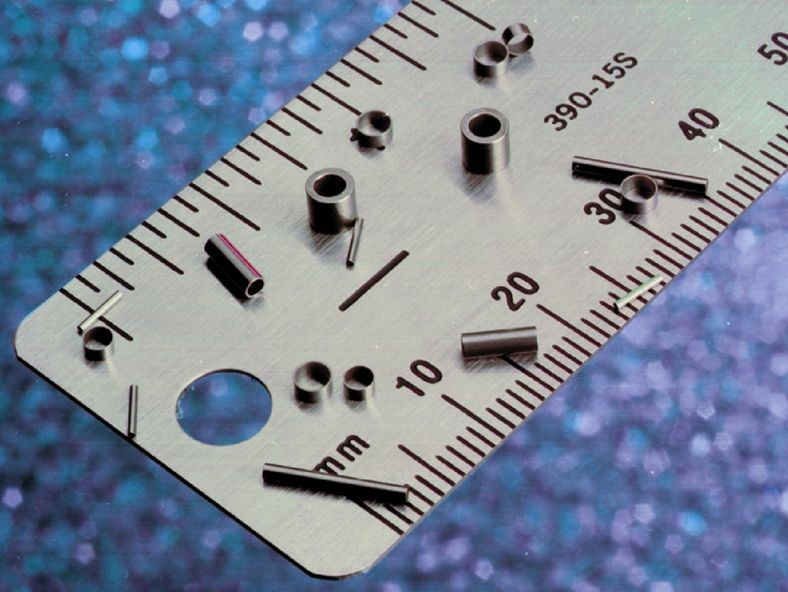

Great Lakes Engineering is a trend setting manufacturer of surface mount stencils, precision laser cut parts, and photo chemical etched parts. We work with a wide range of materials, including Stainless Steel, Copper, Brass, Titanium, Nitinol, Nickel, Kovar and many others.

Our teams at Remaly Manufacturing Company, Inc. utilize state of the art equipment to provide you with laser cutting capabilities. Our teams provide cutting services for a wide range of materials such as steel, aluminum, stainless steel, monel and much more.

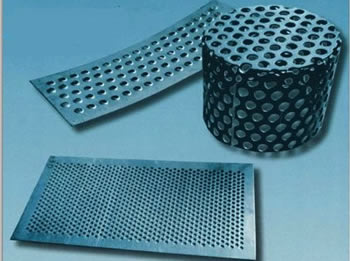

Our fiber optic metal laser cutting capabilities include Stainless steel, Aluminum, CRS and other ferrous and nonferrous metals. We can laser cut flat blanks, stencils, signs, prototypes, and custom formed fabricated parts.

Sharpe Products specializes in custom pipe and tube bending and tube laser cutting. With three powerful, 4kW laser cutting systems, and a robotic, multi-axis 3 kW laser cutting system, we cut round, square, rectangle and open profiles, up to 6-inch OD. Typical cutouts include angles, copes, notches, perforations, slots, or other custom hole patterns, either before or after tube bending. We...

Our laser cutting services are used by leading manufacturers. We have a 10k square foot laser production facility with cutting capabilities up to .625” on steel which processes material quickly. Stocking much carbon steel allows us to pass along the savings. We serve automotive & trucking industries.

More Laser Etching Companies

Etching can be done on various materials, including glass, marble, stone, tile, wood, cardboard, aluminum, stainless steel, wood, paper, cork, plastic, and several polymers. The primary distinction between laser etching and laser engraving is that while engraving removes material to produce deep lines, etching melts the microsurface to produce raised marks. Both procedures apply intense heat to metal surfaces to leave permanent marks. The employment of both procedures is prevalent for part traceability. While laser engraving is more robust, laser etching is faster.

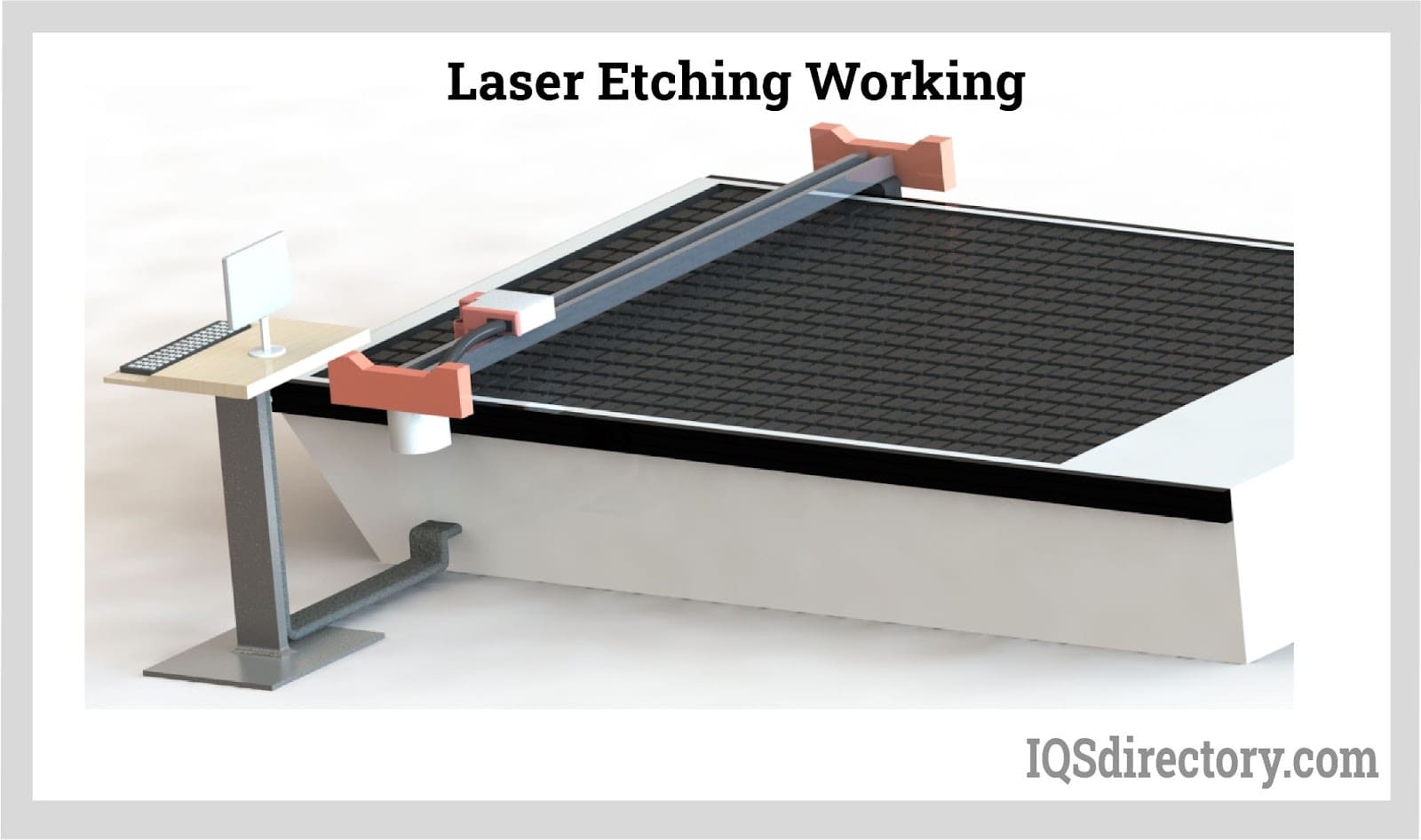

How Does Laser Etching Work?

Laser etching is the process of accurately reproducing images, letters, and numbers from a computer file on a material's surface using a fiber laser machine that produces a light beam at a certain wavelength. One feature that unites all laser marking techniques is pulsing the laser beam, delivering quick bursts of energy at predetermined intervals. Each pulse has a millijoule of energy and a maximum output of 10,000 watts. These pulses produced can be up to one hundred thousand in a second. The pulses are further apart because laser etching a metal uses less energy per area than engraving it.

Types of Laser Etching Machines

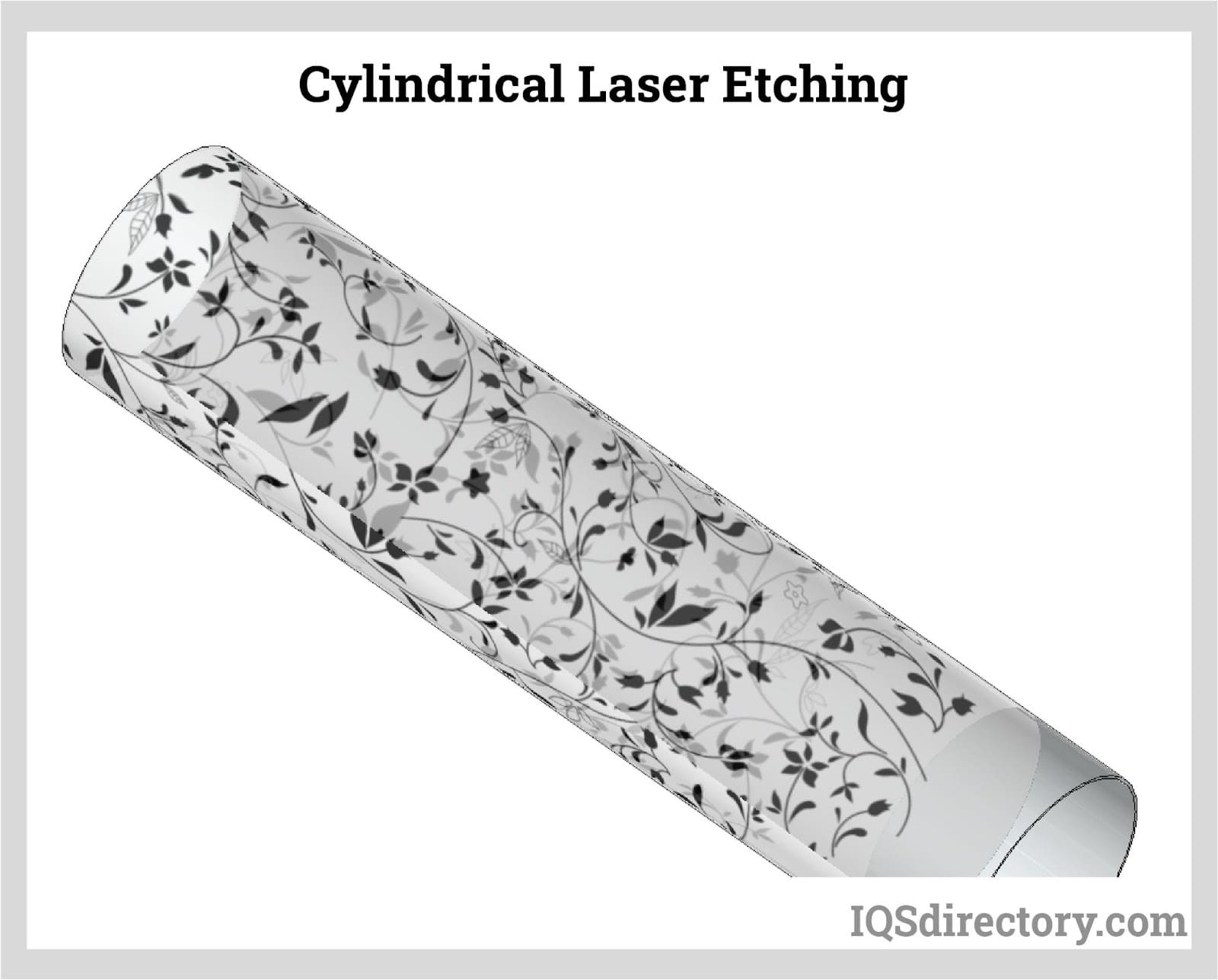

Cylindrical Laser Etching Machine

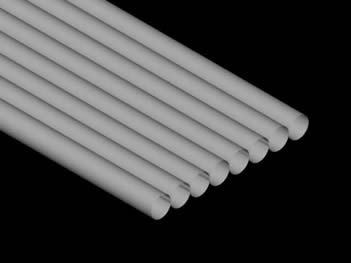

It is more difficult to laser etch cylindrical products such as tumblers, mugs, cups, and wine glasses than flat ones. This is because engraved cylindrical items require careful 360° rotation. When using cylindrical workpieces installed on flat surfaces, the cylindrical type of laser etching equipment successfully traverses a fine helix. These laser etching devices produce the necessary raster image using on-off laser pulsing.

Fixed Laser Etching Machines

There is also a second class of laser etching devices where the workpiece and the laser system are fixed or stationary. Galvo mirrors are utilized in these devices to move the laser beam around the material's surface while it engraves a design. One can use both vector and raster modes with this laser etching technology.

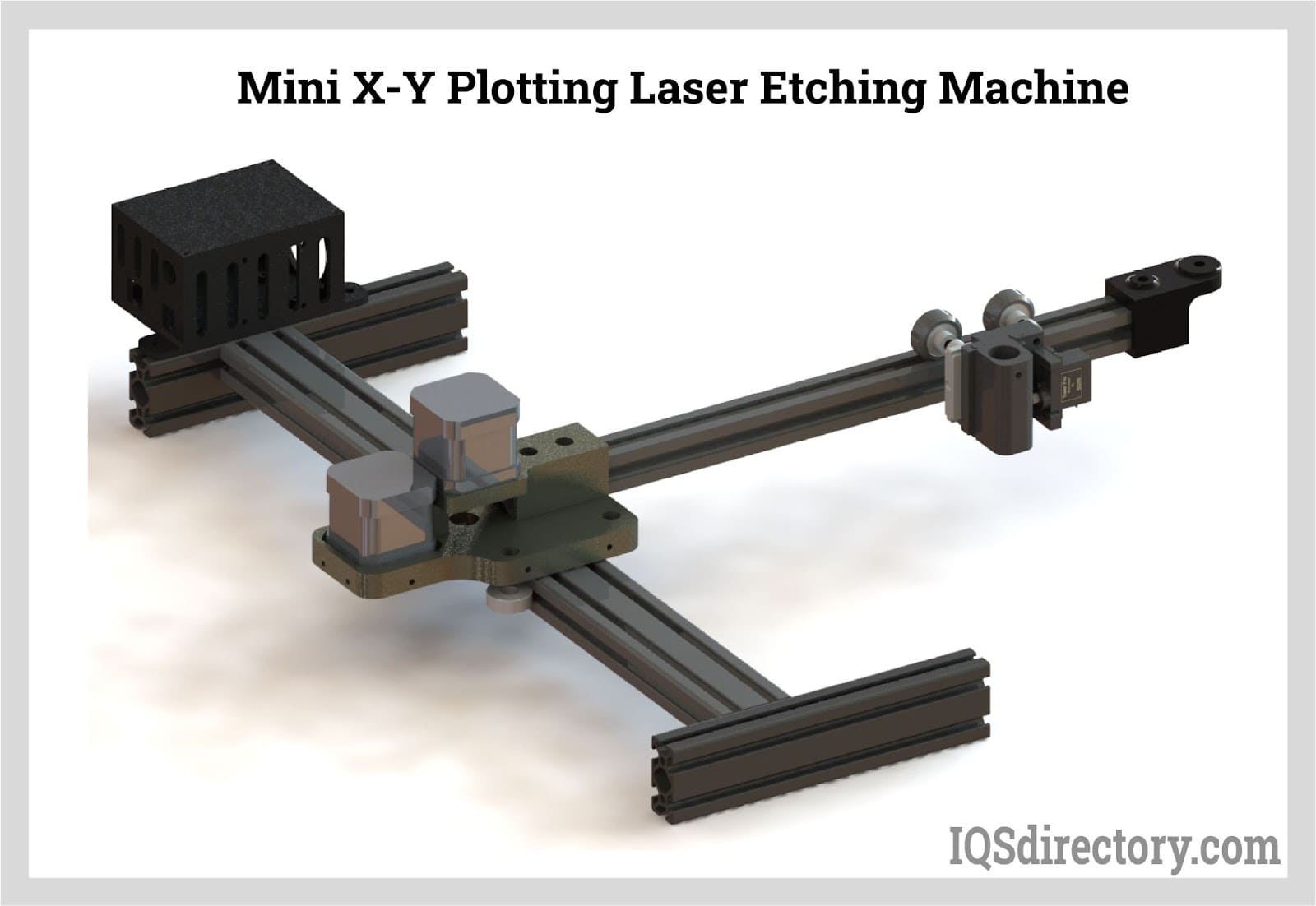

X-Y Type Laser Machine

The most commonly used laser etching equipment is of the X-Y kind. These devices typically have a mobile laser system and a stationary workpiece or surface. The laser is unrestricted in its ability to move in two dimensions. In some devices, the surface is moveable, but the laser system is stationary. In a select few machines, the surface moves on one axis while the laser system travels on the other.

Applications of Laser Etching

- Laser etching can be used to permanently label heat-treated items. Etching will go faster if the component is still warm and may even call for a lower-power laser.

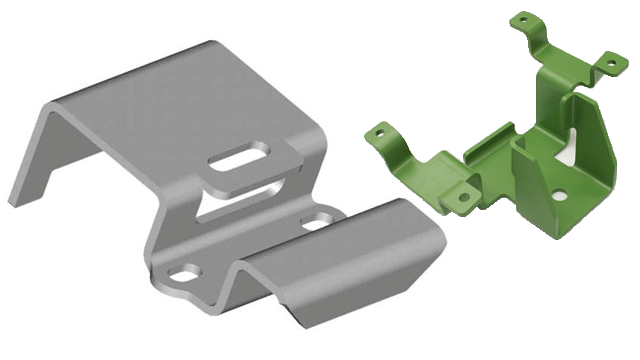

- Raised marks that keep traceability after post-treatments, like powder coating and e-coating, can be made by laser etching. For automobile parts and coated extrusions, many manufacturers utilize laser etching. In addition, etching and engraving are occasionally combined to achieve stronger contrast through thick coats.

- Laser etching is the most effective method for production applications. It not only leaves lasting markings but also provides the best contrast and fastest marking speed.

- Due to the process' accuracy and durability for tracing parts, it is widely used in sectors like the automotive and medical component industries.

Benefits of Laser Etching

- Wide range of applications –manufacturers may use laser etching with various materials, including acrylics, paper, wood, and (most frequently) metals.

- Effective for both thick and thin materials – Since it is compatible with both thick and thin materials, laser etching is an effective or adaptable method of fabricating metal to engrave exquisite creative designs.

- Cost-effective – Laser etching reliably produces cost-effective and precise parts. In addition, laser marking equipment uses very little power; as a result, operating expenses are lower.

- High precision – The laser’s markings are highly exact, making it perfect for marking small details on various products, such as jewelry.

- Time and labor-efficient process – Compared to other laser marking methods, it moves twice as quickly. Therefore, it is crucial for those who need quick mass production marking or have tight deadlines due to the quick process.

Choosing the Correct Laser Etching Company

To ensure you have the most positive outcome when selecting a laser etching company, it is important to compare several businesses using our directory of laser etching businesses. Each laser etching company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each laser etching company website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple laser etching companies with the same form.

Broaching

Broaching CNC Machining

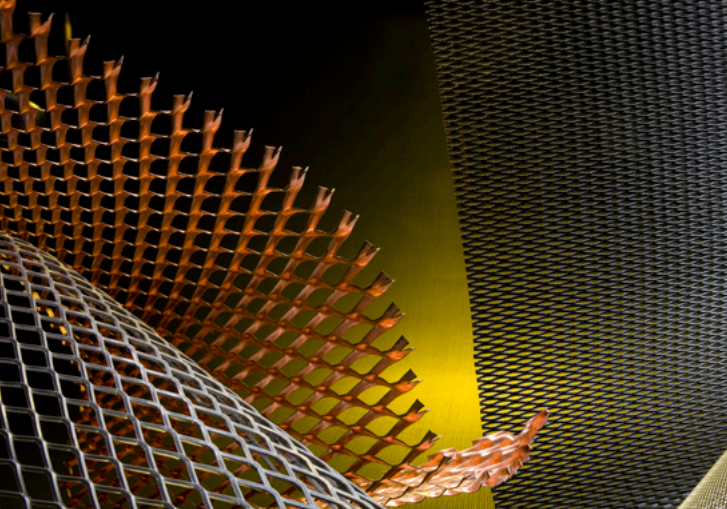

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services