Ridge Engineering, Inc.

Ridge Engineering, Inc.Request A Quote

Hampstead, MDRidge Engineering is a cutting-edge manufacturing company that specializes in precision laser cutting products and services. Based in the United States, the company has a reputation for producing high-quality, customized metal products that meet the most demanding industry requirements. Laser cutting is one of Ridge Engineering's core competencies. The company uses state-of-the-art laser cutting machines that are capable of cutting through a wide range of materials, including stainless steel, aluminum, brass, copper, and carbon steel. With the use of advanced CAD/CAM software, the company can produce highly accurate, intricate cuts with a high degree of precision and repeatability. Ridge Engineering's laser cutting service is suitable for a wide range of industries, including aerospace, automotive, defense, medical, and telecommunications. The company's laser cutting machines are capable of cutting complex shapes, intricate patterns, and precise holes in metal sheets up to 1 inch thick. The company's advanced software allows it to produce parts with tight tolerances and high repeatability, ensuring that every part meets the exacting standards of its customers. In addition to laser cutting, Ridge Engineering also offers a range of value-added services, including design assistance, material sourcing, finishing, and assembly. The company's design team can work with customers to create custom parts or improve existing designs to meet their specific needs. The company's material sourcing team can help customers select the right material for their application, ensuring that the parts meet the required specifications. Ridge Engineering's finishing services include a variety of options, including deburring, polishing, and powder coating, to give parts a professional finish. The company's assembly services can help customers save time and money by providing a fully assembled product that is ready to use upon delivery. Ridge Engineering is committed to providing excellent customer service and strives to build long-term relationships with its customers. The company's experienced staff can help customers with every aspect of their project, from design to delivery, ensuring that they receive a high-quality product that meets their exact specifications. Overall, Ridge Engineering is a premier laser cutting service provider that offers customized solutions to meet the most demanding industry requirements. With its advanced technology, experienced staff, and commitment to customer service, Ridge Engineering is well-positioned to meet the needs of customers in a wide range of industries.

Broaching

Broaching CNC Machining

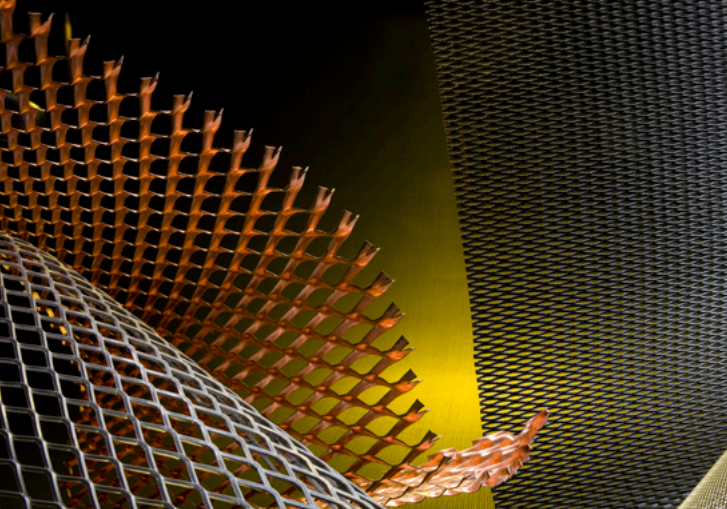

CNC Machining Expanded Metals

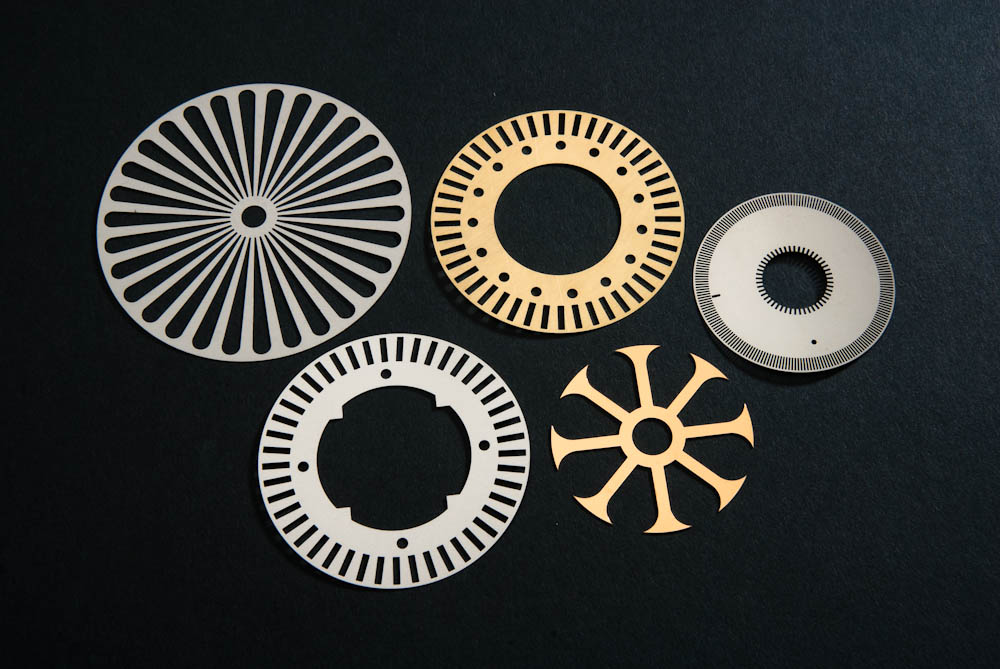

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

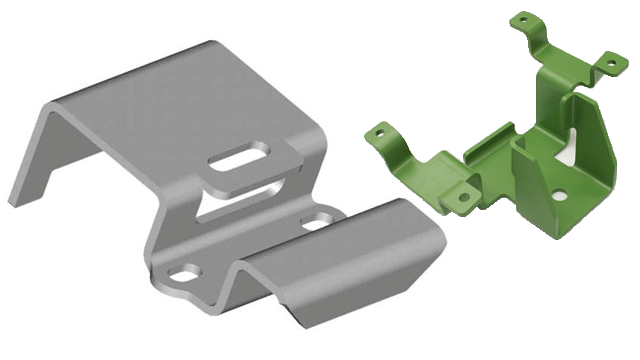

Metal Etching Metal Fabrication

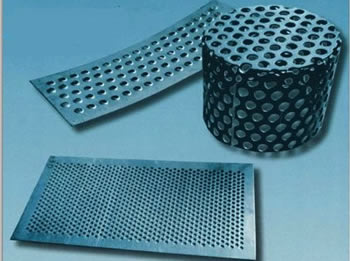

Metal Fabrication Perforated Metals

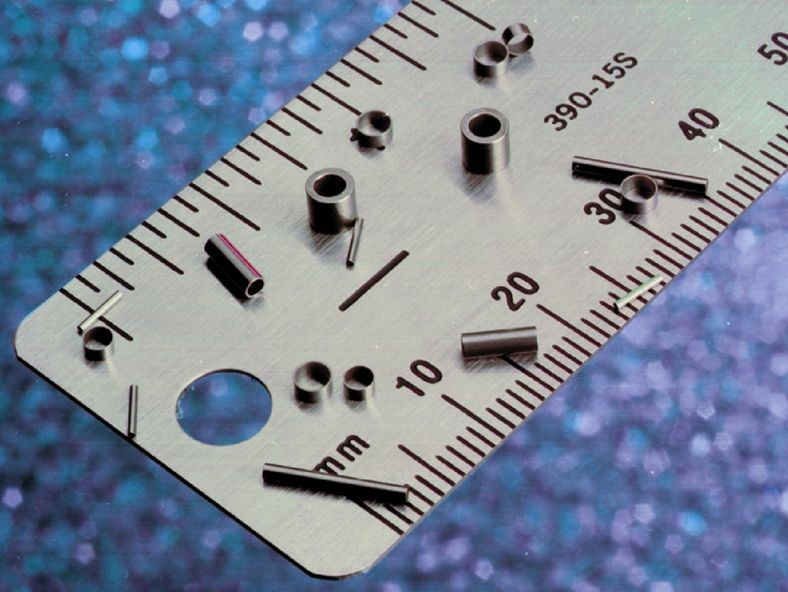

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

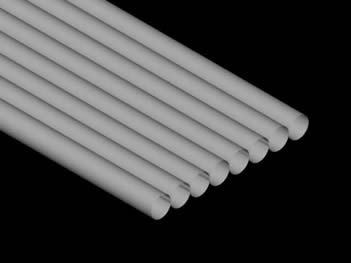

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services